Have only had a minimum of time this week to move along with Crookwell Station...

I have decided to detail the "innards" of the waiting room (at least) and all of this has to be completed before the roof assembly is attended to. Seems a waste of time to detail the interior and not provide lighting to enhance the scene, soooo this is another chore that will need to be achieved before the roofing contractors move in.

During my visit to Crookwell last weekend I took a plethora of detail photos and these have been invaluable in an attempt to portray the feel for the station and other infrastructure. The waiting room seating was one aspect that I wanted to portray accurately and I think I have achieved the feel and accuracy I was striving for. I would imagine I have visited the station over 40 or so times but there is always another aspect that needs to be checked and rechecked and our closeness to "Hooterville" makes this task somewhat easier...added to this is the fact that there is always something previously unseen, no matter how often you visit this time capsule called Crookwell

Another aspect that has required much research, is the exact prototypical length of the platform and facing. Most printed matter refers to Crookwell as either a 100' platform or a 42 metre platform, while some articles refer to both measurements in the same breath. A simple conversion suggests that these two dimensions vary wildly from each other and almost certainly (unless there has been significant fundamental changes to Crookwell over the years)...the quoted 100' length is certainly in error.

Indeed the only firm ( and hopefully reliable) dimension that I have been able to unearth, is the Departmental, Signal Arrangements Diagram issued in 1902 at the time of the line's opening, which indicate a total dimension (including ramps) of 45 and 1/3 yards which when converted ends up around 41.5 metres which will be close enough to 42 metres for me !!! Never occurred to me to measure the damn thing before the fairly recent and questionable modifications to the platform took place.

I will sometime this week laser up the base that will hold the station building, platform and facing, fencing, signage and other items all in one mini diorama for later fitment to the layout...

NSWGR Southern Line Layout In A Shed

A NSW HO Branch Layout Takes Shape

Sunday, 6 September 2015

Monday, 31 August 2015

Crookwell...The Groundwork Continues

Planning and decisions continue to be made for the proposed Crookwell Layout. Firstly is the decision to hand lay all track and utilise Fast Tracks jigs to manufacture required points. I am hoping that the jigs will accept code 75 rail as I have an abundance of Peco rail. I have the ability to laser up all general sleepers, point sleepers and rail fish plates and this will lower the overall cost of required accessories. In the wash up, I feel that this layout will certainly benefit from hand laid track.

As the building of all infrastructure items moves ahead, I decided that a visit to Crookwell was in order and with the girls in tow, we took a drive out there yesterday and made a day of it. I took an absolute plethora of shots to add to my rather extensive existing collection, but with a layout now being the focus, attention moved to the "micro" elements rather than the overall feel. Of course all things have a habit of changing in the prototype world and Crookwell Station precinct is no different with some major modifications taking place since my last visit earlier in the year. I am not convinced that all of the changes have improved the appeal of the place as a tourist attraction...but the area is well maintained, neat and tidy.

With the construction of the A5 station building well underway, I was also keen to measure a myriad of detail items to ensure integrity with the model is maintained. Most important was the internal details of the waiting room as this will be a focal point due to it being on display as an open type waiting room. The station building will be part of a small, self contained, diorama that will include the platform, facing, lamp room and toilet (C4) and some rear scenery. This method should allow me to work on the details away from the layout and when complete the "diorama" will then be placed and blended into the surrounds.

I was also especially interested in studying the area immediately around the yard throat and out towards the down home signal location. This area will also become a scenery break on the layout and the low timber trestles/bridges that carry the line over the Kiama Creek in two locations were also of interest. Time has certainly taken it's toll on both structures but all dimensions were recorded as well as the construction methods and these two structures that flank the Harley Road level crossing will certainly be a focal point on the layout.

More to follow!

As the building of all infrastructure items moves ahead, I decided that a visit to Crookwell was in order and with the girls in tow, we took a drive out there yesterday and made a day of it. I took an absolute plethora of shots to add to my rather extensive existing collection, but with a layout now being the focus, attention moved to the "micro" elements rather than the overall feel. Of course all things have a habit of changing in the prototype world and Crookwell Station precinct is no different with some major modifications taking place since my last visit earlier in the year. I am not convinced that all of the changes have improved the appeal of the place as a tourist attraction...but the area is well maintained, neat and tidy.

With the construction of the A5 station building well underway, I was also keen to measure a myriad of detail items to ensure integrity with the model is maintained. Most important was the internal details of the waiting room as this will be a focal point due to it being on display as an open type waiting room. The station building will be part of a small, self contained, diorama that will include the platform, facing, lamp room and toilet (C4) and some rear scenery. This method should allow me to work on the details away from the layout and when complete the "diorama" will then be placed and blended into the surrounds.

|

| Progress on the station is coming along...The actual colour does not present well in the photos...it is in essence an off white colour... |

|

| Façade, eaves, barge boards and finials fitted...vents will be fitted in the coming days as well as other internals |

|

| Waiting room floor can be glimpsed as well as a start being made on the chimney structure....Once all internals are complete, the roof trusses and assembly will be fitted... |

|

| How Crookwell Station presents today... |

I was also especially interested in studying the area immediately around the yard throat and out towards the down home signal location. This area will also become a scenery break on the layout and the low timber trestles/bridges that carry the line over the Kiama Creek in two locations were also of interest. Time has certainly taken it's toll on both structures but all dimensions were recorded as well as the construction methods and these two structures that flank the Harley Road level crossing will certainly be a focal point on the layout.

|

| Looking back (up direction) towards Goulburn... The Down Home signal can just be seen in the depths of the cutting as viewed from Harley Road. |

|

| Looking in the up direction with the yard entrance behind me. Harley Road level crossing can be seen. |

More to follow!

Sunday, 23 August 2015

Long Time Between Drinks...

It has been some time since my last post and plenty has happened in the intervening period...

Firstly, the layout once known as Fish River has been permanently closed with all track being removed and once the river scene and bridges have been "detonated", as in true NSWGR style...little will remain of this location for rail historians to trace in years to come...

As readers will no doubt be aware, I have been at "loggerheads" with my modelling for some time and with much soul searching over that time, have arrived at what I think has been the underlying problem. Simply put, I think I "bit off more than I could chew" with the original layout in terms of size. With an area of 12m x 3.5m to play with and a fairly full "other" life...I could never anticipate a time when the originally planned layout would ever reach a state of completion that would satisfy me. While I am certainly a disciple of the "it's the enjoyment of the journey... not the end" logic...I could not see it working with the present project.

I think a secondary issue may well have been the decision to model a "freelance" location rather than a prototype location that I could identify with, either extinct or still in existence. Either way I was not really progressing on any front and as much as I knew that model railways would always be a part of my life, I needed to find a happy place rather than the regular pilgrimages to the shed, that ended in frustration some 5 minutes after arrival and a swift return to the house.

I had examined the possibility of modelling the Crookwell Line ( a line that branched from Goulburn NSW) not long after moving down here in 2002 but at that time I had visions of a "vast empire" and the ability of continuous running...so that idea was shelved very early in the piece. With my present "malaise" washing around in my head and during a regular visit to Crookwell, late last year, the idea once again surfaced and a firm decision to go ahead was made over the winter months. It is ironic that the Australian Model Railway Magazine had an article in the latest magazine regarding Crookwell as a modelling proposition.

The attractions of such a line in model form, are many...but for me the following facts were to push it across the line. It is on my doorstep with the line leaving Goulburn and with Crookwell ( the terminus) being only 40km by road from home, it is easily identifiable. The yard and station environs at Crookwell are relatively intact. There is a goodly amount of research material locally available, making modelling decisions an easier proposition. The loco requirements are fairly small in both numbers and classes that traversed the line with rolling stock also falling into a comparatively narrow type of traffic.

I have decided to model the terminus of Crookwell and at least one or two intermediate stations. Maybe "Roslyn" will come into play and depending on the period chosen will also allow the junction of the Taralga line to be either modelled as open...or after closure with the earthworks still evident.

The basic infrastructure requirements for Crookwell station and yard are: A5 station building ( presently under construction) a C4 lamp room and toilet at the end of the platform, a G3 goods shed (under construction), a 5 ton overhead crane, 50' or 60' Sellers turntable, depending on the era modelled and I will be utilising a recently purchased Anton's 60' Sellers unit and an elevated water tank and stand (already have) A small cattle and separate sheep loading platform and loading bank just about exhausts the requirements.

All DCC equipment, panels, wiring and Cobalt point motors can be recycled and it is more than likely I will introduce signalling and interlocking due to the minimal numbers required...so the new layout should end up being fairly "finance neutral" which is also an attractive point in the equation.

In relation to the layout "fit", the proposed Crookwell Branch will only require 3 walls of the larger layout room and allow the duck under to be permanently removed and this also is a major benefit as my back stacks on the years.

I guess as we all get older, our wants and expectations from the hobby change and in this decision, I anticipate that every segment of the hobby I enjoy will be available in manageable and equal proportions with an achievable personal outcome being the end result. I certainly don't harbour any regrets with my past decisions as all I know is that my hunger has returned to a level that I have not experienced for years, and even my blogging should now have a purpose...

I have included some photos of progress on the new venture...

Firstly, the layout once known as Fish River has been permanently closed with all track being removed and once the river scene and bridges have been "detonated", as in true NSWGR style...little will remain of this location for rail historians to trace in years to come...

As readers will no doubt be aware, I have been at "loggerheads" with my modelling for some time and with much soul searching over that time, have arrived at what I think has been the underlying problem. Simply put, I think I "bit off more than I could chew" with the original layout in terms of size. With an area of 12m x 3.5m to play with and a fairly full "other" life...I could never anticipate a time when the originally planned layout would ever reach a state of completion that would satisfy me. While I am certainly a disciple of the "it's the enjoyment of the journey... not the end" logic...I could not see it working with the present project.

I think a secondary issue may well have been the decision to model a "freelance" location rather than a prototype location that I could identify with, either extinct or still in existence. Either way I was not really progressing on any front and as much as I knew that model railways would always be a part of my life, I needed to find a happy place rather than the regular pilgrimages to the shed, that ended in frustration some 5 minutes after arrival and a swift return to the house.

I had examined the possibility of modelling the Crookwell Line ( a line that branched from Goulburn NSW) not long after moving down here in 2002 but at that time I had visions of a "vast empire" and the ability of continuous running...so that idea was shelved very early in the piece. With my present "malaise" washing around in my head and during a regular visit to Crookwell, late last year, the idea once again surfaced and a firm decision to go ahead was made over the winter months. It is ironic that the Australian Model Railway Magazine had an article in the latest magazine regarding Crookwell as a modelling proposition.

The attractions of such a line in model form, are many...but for me the following facts were to push it across the line. It is on my doorstep with the line leaving Goulburn and with Crookwell ( the terminus) being only 40km by road from home, it is easily identifiable. The yard and station environs at Crookwell are relatively intact. There is a goodly amount of research material locally available, making modelling decisions an easier proposition. The loco requirements are fairly small in both numbers and classes that traversed the line with rolling stock also falling into a comparatively narrow type of traffic.

I have decided to model the terminus of Crookwell and at least one or two intermediate stations. Maybe "Roslyn" will come into play and depending on the period chosen will also allow the junction of the Taralga line to be either modelled as open...or after closure with the earthworks still evident.

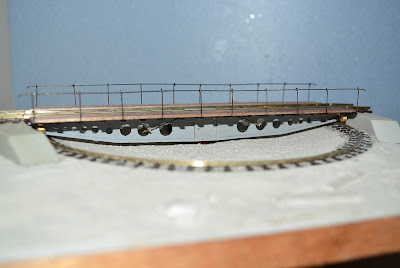

The basic infrastructure requirements for Crookwell station and yard are: A5 station building ( presently under construction) a C4 lamp room and toilet at the end of the platform, a G3 goods shed (under construction), a 5 ton overhead crane, 50' or 60' Sellers turntable, depending on the era modelled and I will be utilising a recently purchased Anton's 60' Sellers unit and an elevated water tank and stand (already have) A small cattle and separate sheep loading platform and loading bank just about exhausts the requirements.

All DCC equipment, panels, wiring and Cobalt point motors can be recycled and it is more than likely I will introduce signalling and interlocking due to the minimal numbers required...so the new layout should end up being fairly "finance neutral" which is also an attractive point in the equation.

In relation to the layout "fit", the proposed Crookwell Branch will only require 3 walls of the larger layout room and allow the duck under to be permanently removed and this also is a major benefit as my back stacks on the years.

I guess as we all get older, our wants and expectations from the hobby change and in this decision, I anticipate that every segment of the hobby I enjoy will be available in manageable and equal proportions with an achievable personal outcome being the end result. I certainly don't harbour any regrets with my past decisions as all I know is that my hunger has returned to a level that I have not experienced for years, and even my blogging should now have a purpose...

I have included some photos of progress on the new venture...

|

| The last remnants of the existing layout...sadly will succumb to the NSWGR wrecking crew... |

|

| Proposed location of the Crookwell terminus pretty much ready for tracklaying to commence. |

|

| Crookwell Station under construction...all laser cut basswood and acrylic base. All components have been drawn for the next round of lasering, with the roof assembly to come next |

|

| 60' Sellers Turntable which only needs some detail and weathering before being installed... |

Thursday, 5 March 2015

A Mixed Bag...

All,

Before I get down to the modelling side of things, it would be remiss of me not to pay homage to our latest New South Wales preserved steam recruit. Following an extensive rebuild in Canberra and a couple of trial trips to Goulburn, Beyer Garratt locomotive 6029 finally stretched her legs on the Main South and was a star attraction throughout last weekend. Fortunately, I live opposite the main south railway at North Goulburn and captured it's passing last weekend. I had planned to chase it but due to the foggy conditions, made do with a couple of shots out the front, comfortable in the knowledge that we will see much of this loco in the future. I have included one of the original shots and also had a play in Lightroom to recreate the past in black and white...anyway, I hope our OS modelling friends also enjoy a view of our newest preserved kettle.

And now back to the modelling....

Earlier today I received a package from Mike at DCCSound which contained the much anticipated "voice box" for my Auscision 45 Class.

Much has been written regarding these locos...so as to not bore everyone with yet another review of this release, I thought I would just offer my experiences with the DCC and sound conversion.

First things first, and following the obligatory perusal of the loco instruction sheet...disassembly was commenced. It may well be that Murphy decided to pay a visit to the workbench but the normally simple removal of the couplers proved to be a real pain in the proverbial. Due to coupler box / pilot clearances, they certainly were not about to slide out through the pilot forwards and so after a period of cajoling, I finally had to slide the coupler boxes inboard until the coupler trip pin was against the pilot and then remove the coupler box lid ( again inboard ) and this then allowed the removal of the coupler tang forward and the coupler box base and sheet spring were then removed from behind the pilot as well. (Reassembly was obviously the reverse of this fiddly method). With the couplers now removed and the four chassis / body screws removed, the body came away very easily indeed.

As I have said in earlier posts, I do like Tsunami decoders, but as Auscision persist with 21 pin sockets on the boards and the lighting circuits become more intricate...I will continue to utilise DCC Sound on this manufacturers offerings. Installation of the decoder is very simply a case of removing the existing board and plug in the Loksound offering. Care has to be taken due to the length and relative fragility of the pins. Orientation of the decoder is also important but close inspection of the dummy pin and decoder plug should ensure all goes well. In this case the decoder is fitted under the main loco board and is a very close fit with the speaker enclosure. The overhang of the decoder is also an issue to keep an eye on and I finished the installation with Kaptan tape to ensure the decoder did not become dislodged over time and to also keep the two mating parts ( decoder and main board ) parallel. The supplied speaker is a very nice and snug fit to the enclosure and the only gap that requires sealing is the speaker wire recess in the speaker enclosure. All in all a very neat conversion.

I programmed the loco earlier this evening and as much as I have had no time to fiddle with the settings with Decoder Pro... the "factory settings" sound and operation is stunning. Unlike the DCCSound 48 class decoder volume issue...the 45 class offering is quite "audible" straight out of the box and more than likely the master volume will require reduction at some time in the future. The sound quality is unmistakably "45 Class" and to my ears is nothing short of stunning and a credit to Mike and the DCCSound team. Presently the loco is set to 28 speed steps and performs brilliantly with silky smooth start up and very nice momentum ( straight out of the box ).

Before I get down to the modelling side of things, it would be remiss of me not to pay homage to our latest New South Wales preserved steam recruit. Following an extensive rebuild in Canberra and a couple of trial trips to Goulburn, Beyer Garratt locomotive 6029 finally stretched her legs on the Main South and was a star attraction throughout last weekend. Fortunately, I live opposite the main south railway at North Goulburn and captured it's passing last weekend. I had planned to chase it but due to the foggy conditions, made do with a couple of shots out the front, comfortable in the knowledge that we will see much of this loco in the future. I have included one of the original shots and also had a play in Lightroom to recreate the past in black and white...anyway, I hope our OS modelling friends also enjoy a view of our newest preserved kettle.

And now back to the modelling....

Earlier today I received a package from Mike at DCCSound which contained the much anticipated "voice box" for my Auscision 45 Class.

Much has been written regarding these locos...so as to not bore everyone with yet another review of this release, I thought I would just offer my experiences with the DCC and sound conversion.

First things first, and following the obligatory perusal of the loco instruction sheet...disassembly was commenced. It may well be that Murphy decided to pay a visit to the workbench but the normally simple removal of the couplers proved to be a real pain in the proverbial. Due to coupler box / pilot clearances, they certainly were not about to slide out through the pilot forwards and so after a period of cajoling, I finally had to slide the coupler boxes inboard until the coupler trip pin was against the pilot and then remove the coupler box lid ( again inboard ) and this then allowed the removal of the coupler tang forward and the coupler box base and sheet spring were then removed from behind the pilot as well. (Reassembly was obviously the reverse of this fiddly method). With the couplers now removed and the four chassis / body screws removed, the body came away very easily indeed.

As I have said in earlier posts, I do like Tsunami decoders, but as Auscision persist with 21 pin sockets on the boards and the lighting circuits become more intricate...I will continue to utilise DCC Sound on this manufacturers offerings. Installation of the decoder is very simply a case of removing the existing board and plug in the Loksound offering. Care has to be taken due to the length and relative fragility of the pins. Orientation of the decoder is also important but close inspection of the dummy pin and decoder plug should ensure all goes well. In this case the decoder is fitted under the main loco board and is a very close fit with the speaker enclosure. The overhang of the decoder is also an issue to keep an eye on and I finished the installation with Kaptan tape to ensure the decoder did not become dislodged over time and to also keep the two mating parts ( decoder and main board ) parallel. The supplied speaker is a very nice and snug fit to the enclosure and the only gap that requires sealing is the speaker wire recess in the speaker enclosure. All in all a very neat conversion.

I programmed the loco earlier this evening and as much as I have had no time to fiddle with the settings with Decoder Pro... the "factory settings" sound and operation is stunning. Unlike the DCCSound 48 class decoder volume issue...the 45 class offering is quite "audible" straight out of the box and more than likely the master volume will require reduction at some time in the future. The sound quality is unmistakably "45 Class" and to my ears is nothing short of stunning and a credit to Mike and the DCCSound team. Presently the loco is set to 28 speed steps and performs brilliantly with silky smooth start up and very nice momentum ( straight out of the box ).

|

| Overall view of the loco chassis with decoder and speaker fitted... |

|

| Decoder shown in position under the main board...note clearance of decoder and speaker box...and decoder overhang which needs to be supported... |

|

| Close up of Decoder and speaker after installation...wiring to be tidied up and Kaptan tape fitted... |

|

| And to finish with a prototype picture... 4520+4490+44211 returning to Sydney (through North Goulburn) at the head of the 2010 Melbourne Cup charter train |

Sunday, 22 February 2015

Sprogs!!!...And Other Things...

All,

Prior to my layout hiatus, one of the constant sources of annoyance was the need to be "trackside" when wanting to explore the decoder settings of my fleet of locomotives. As I have stated before, I use NCE for the layout operation and with Cobalt point motors and panel mounted Cobalt decoders I am able to either utilise the panel or the NCE handpiece for layout control and all works well. On the locomotive/rollingstock front, I have a mix of QSI, Tsunami and ESU or Loksound decoders, and given the advances with DCC/Sound decoders I would imagine that this variety will grow. I certainly have grown to favour Soundtraxx Tsunami for a number of reasons but feel reticent to pull a perfectly brand new loco or railmotor apart just to change the decoder.

While it is perfectly reasonable to assume that a factory fitted DCC/Sound loco purchase should work adequately straight from the box, and some people are quite happy to do so...I like to constantly learn about and tweak the performance and attempt to have my locos performing and sounding in a fashion that satisfies ME. I do think at times that this holy grail of operational/sound perfection is an "urban myth" but nonetheless the upside of all of this reading and tweaking is that I have a better understanding of just what makes my locos tick and now have the confidence to at least attempt to exploit the seemingly endless possibilities that DCC can offer.

Some years ago, following the successful conversion of an Austrains 442 to Tsunami, I took the plunge and downloaded JMRI Decoder Pro and Panel Pro software. As an aside, in this increasingly commercial world... it still baffles me that this brilliant software is free...but I digress. The software loads beautifully but connecting the PC ( via serial cable ) to an NCE system can be trial and error and dependant on the serial cable being configured correctly. Once successful configuration is achieved...a whole new world of DCC awaits...

Now that I am forging ahead with the layout, the ability to programme locomotives has again become a necessity and as alluded to in the first paragraph of this post, I needed a more convenient method that allows the programming to be carried out quite separately and untethered to the NCE system and train room.

Enter the SPROG!. Apart from a slang terminology for a child, I have no idea why the name SPROG was chosen for the DCC command station....maybe the fact that the unit is so small is why it was coined with that name. While it may be small, it is a brilliant piece of equipment, easily setup and configured and quite portable...all the attributes I had been looking for.

As can be seen from the above shot, connections are quite simple. Power in x 2 and Track out x 2 (on the left) and USB connection to PC or laptop in this case ( on the right ). Installation of the PC drivers is very straightforward unless utilising Windows 8 or 8.1 which required a bit more juggling about...but still relatively easy...even for this scribe.

As much as the unit ships with an installation disk...this does not assure the latest incarnations and updates of all software...so my advice is to download the latest releases of DecoderPro and PanelPro directly from the JMRI site prior to installation of the SPROG. I also took the opportunity of downloading the user manuals and supplementary notes on installation to a PC operating under Win8 or 8.1.

The only other piece of equipment required is a power supply for the SPROG. The requirements suggest a regulated power supply 12-18V, 3 A. There are several "solves" available but I elected to also purchase a Cobalt PSU2+ power supply with Dual 9 V regulated or bridgeable 18V supply at 5A. This unit may be overkill and there are plenty of cheaper wall plug type power supplies, but I have wanted one of these for a while to try out as a dedicated point motor supply..so the decision was a convenient no brainer.

I guess it is timely to mention that the SPROG3 and Power Supply were both purchased from DCC Concepts in WA and were delivered to regional NSW within 48 hours of ordering...In comparison it took around 9 working days to receive my Traino 48 Class from Sydney...so hats off to the guys at DCC Concepts...

I have also fabricated a test track and base that is 1.3 metres in length and houses the SPROG unit and associated wiring. This test track is also portable, so coupled with a laptop computer, research, learning and programming can be carried out almost anywhere.

In conclusion, the SPROG's ease of installation, ease of use portability and seamless integration with the JMRI suite of programmes has been a complete game changer for me. I have no idea why I did not purchase the earlier versions of the SPROG...but better late than never. Those bitterly cold late night trips to the layout room in the dead of winter, to spend some time loco programming are a thing of the past and I will be spending some more time looking closely at the offerings of the PanelPro software as well... While SPROG and DecoderPro are not cure all panaceas for all brands of decoders...they certainly offer a high level of easy programming and an unrivalled way to learn the secrets behind the dreaded CVs...

Of course the SPROG is not new...and many DCC-ites will have availed themselves of it for a great many years...but I will post another instalment of the SPROG and JMRI software in practice... if readers would like...We will learn together!

Prior to my layout hiatus, one of the constant sources of annoyance was the need to be "trackside" when wanting to explore the decoder settings of my fleet of locomotives. As I have stated before, I use NCE for the layout operation and with Cobalt point motors and panel mounted Cobalt decoders I am able to either utilise the panel or the NCE handpiece for layout control and all works well. On the locomotive/rollingstock front, I have a mix of QSI, Tsunami and ESU or Loksound decoders, and given the advances with DCC/Sound decoders I would imagine that this variety will grow. I certainly have grown to favour Soundtraxx Tsunami for a number of reasons but feel reticent to pull a perfectly brand new loco or railmotor apart just to change the decoder.

While it is perfectly reasonable to assume that a factory fitted DCC/Sound loco purchase should work adequately straight from the box, and some people are quite happy to do so...I like to constantly learn about and tweak the performance and attempt to have my locos performing and sounding in a fashion that satisfies ME. I do think at times that this holy grail of operational/sound perfection is an "urban myth" but nonetheless the upside of all of this reading and tweaking is that I have a better understanding of just what makes my locos tick and now have the confidence to at least attempt to exploit the seemingly endless possibilities that DCC can offer.

Some years ago, following the successful conversion of an Austrains 442 to Tsunami, I took the plunge and downloaded JMRI Decoder Pro and Panel Pro software. As an aside, in this increasingly commercial world... it still baffles me that this brilliant software is free...but I digress. The software loads beautifully but connecting the PC ( via serial cable ) to an NCE system can be trial and error and dependant on the serial cable being configured correctly. Once successful configuration is achieved...a whole new world of DCC awaits...

Now that I am forging ahead with the layout, the ability to programme locomotives has again become a necessity and as alluded to in the first paragraph of this post, I needed a more convenient method that allows the programming to be carried out quite separately and untethered to the NCE system and train room.

|

| Existing Layout Computer with NCE power supply and command station tucked away at left... |

Enter the SPROG!. Apart from a slang terminology for a child, I have no idea why the name SPROG was chosen for the DCC command station....maybe the fact that the unit is so small is why it was coined with that name. While it may be small, it is a brilliant piece of equipment, easily setup and configured and quite portable...all the attributes I had been looking for.

As can be seen from the above shot, connections are quite simple. Power in x 2 and Track out x 2 (on the left) and USB connection to PC or laptop in this case ( on the right ). Installation of the PC drivers is very straightforward unless utilising Windows 8 or 8.1 which required a bit more juggling about...but still relatively easy...even for this scribe.

As much as the unit ships with an installation disk...this does not assure the latest incarnations and updates of all software...so my advice is to download the latest releases of DecoderPro and PanelPro directly from the JMRI site prior to installation of the SPROG. I also took the opportunity of downloading the user manuals and supplementary notes on installation to a PC operating under Win8 or 8.1.

|

| The SPROG II User Guide gives the bulk of the info and is supplemented with the SPROG 3 user guide.. |

The only other piece of equipment required is a power supply for the SPROG. The requirements suggest a regulated power supply 12-18V, 3 A. There are several "solves" available but I elected to also purchase a Cobalt PSU2+ power supply with Dual 9 V regulated or bridgeable 18V supply at 5A. This unit may be overkill and there are plenty of cheaper wall plug type power supplies, but I have wanted one of these for a while to try out as a dedicated point motor supply..so the decision was a convenient no brainer.

I guess it is timely to mention that the SPROG3 and Power Supply were both purchased from DCC Concepts in WA and were delivered to regional NSW within 48 hours of ordering...In comparison it took around 9 working days to receive my Traino 48 Class from Sydney...so hats off to the guys at DCC Concepts...

I have also fabricated a test track and base that is 1.3 metres in length and houses the SPROG unit and associated wiring. This test track is also portable, so coupled with a laptop computer, research, learning and programming can be carried out almost anywhere.

In conclusion, the SPROG's ease of installation, ease of use portability and seamless integration with the JMRI suite of programmes has been a complete game changer for me. I have no idea why I did not purchase the earlier versions of the SPROG...but better late than never. Those bitterly cold late night trips to the layout room in the dead of winter, to spend some time loco programming are a thing of the past and I will be spending some more time looking closely at the offerings of the PanelPro software as well... While SPROG and DecoderPro are not cure all panaceas for all brands of decoders...they certainly offer a high level of easy programming and an unrivalled way to learn the secrets behind the dreaded CVs...

Of course the SPROG is not new...and many DCC-ites will have availed themselves of it for a great many years...but I will post another instalment of the SPROG and JMRI software in practice... if readers would like...We will learn together!

Friday, 13 February 2015

Back In The Saddle...

All,

During the sorting out around here, I unearthed a couple of unopened Rails North BMF Milk Tank kits. I am guessing I purchased these in the mid 80s and by the look of the staples holding the packs together and the rust stains on the instructions ( which incidentally are on foolscap paper ) would imagine they have not seen the light of day in 3 decades. Anyway they took my fancy and I decided to commence construction this afternoon.

I decided to have a play with the tanks to get a feel of just how the wagon will look when complete and the condition of the tanks will give me a guide as to how the decking and underframe will be weathered.

Some time ago, I briefly described the salt weathering method on a structure and decided I wanted to capture the same basic feel with these tanks. There is not a lot of research material on these particular wagons and apart from a vague recollection that the tanks were white...I am flying blind. I also have no idea as to when these wagons were condemned...so it is fair to assume that they would have been a real mess towards the end of their lives and it is this condition that I envisage recreating.

The tanks are a solid cast resin and while this was the rudimentary method of kit manufacture back in the 70s and 80s...it is fortuitous, as the weight of the solid tanks means that very little or no added wagon weight will be required once complete.

I commenced painting the tanks with the normal etch primer...followed by a mix of Tamiya browns to taste. Because the Tamiya paints tend to dry extremely quickly on the painted item, I tend to thin it fairly well so that I end up with plenty of time to apply the salt and still have it adhere to the drying paint. You can at this point continue to paint the wagon with a mix of colours and salt layers so that you end up with several shades of show through colour when the salt is eventually removed. I finish coated the tanks with a "just off white" Lifecolour brand and then set it aside to dry.

When dry...the salt can be rubbed or picked off and the undercolours are revealed. There is another method where the painted object is sprayed with water and the salt applied to the water to adhere it to the surface. It all depends on what you are painting and what you desire the end result to be. In the photos in this post...I have probably overdone the salt to ensure the method is visible...but in most cases less is more and in the case of these tanks I can add another coat to hide some of the simulated pitting marks to lessen the visual impact and can also add rust stain runs to suit...The end result is certainly in the eye of the beholder.

There are so many variations that can be adopted and indeed just the salt added to the rust base colour can create rust bleeds and a kind of rust bloom or "flowering" effect that does not require a top coat...just removal of the salt.

I will post some shots of the wagons construction progress as time goes by...

The photos illustrate the workflow...

During the sorting out around here, I unearthed a couple of unopened Rails North BMF Milk Tank kits. I am guessing I purchased these in the mid 80s and by the look of the staples holding the packs together and the rust stains on the instructions ( which incidentally are on foolscap paper ) would imagine they have not seen the light of day in 3 decades. Anyway they took my fancy and I decided to commence construction this afternoon.

I decided to have a play with the tanks to get a feel of just how the wagon will look when complete and the condition of the tanks will give me a guide as to how the decking and underframe will be weathered.

Some time ago, I briefly described the salt weathering method on a structure and decided I wanted to capture the same basic feel with these tanks. There is not a lot of research material on these particular wagons and apart from a vague recollection that the tanks were white...I am flying blind. I also have no idea as to when these wagons were condemned...so it is fair to assume that they would have been a real mess towards the end of their lives and it is this condition that I envisage recreating.

The tanks are a solid cast resin and while this was the rudimentary method of kit manufacture back in the 70s and 80s...it is fortuitous, as the weight of the solid tanks means that very little or no added wagon weight will be required once complete.

I commenced painting the tanks with the normal etch primer...followed by a mix of Tamiya browns to taste. Because the Tamiya paints tend to dry extremely quickly on the painted item, I tend to thin it fairly well so that I end up with plenty of time to apply the salt and still have it adhere to the drying paint. You can at this point continue to paint the wagon with a mix of colours and salt layers so that you end up with several shades of show through colour when the salt is eventually removed. I finish coated the tanks with a "just off white" Lifecolour brand and then set it aside to dry.

When dry...the salt can be rubbed or picked off and the undercolours are revealed. There is another method where the painted object is sprayed with water and the salt applied to the water to adhere it to the surface. It all depends on what you are painting and what you desire the end result to be. In the photos in this post...I have probably overdone the salt to ensure the method is visible...but in most cases less is more and in the case of these tanks I can add another coat to hide some of the simulated pitting marks to lessen the visual impact and can also add rust stain runs to suit...The end result is certainly in the eye of the beholder.

There are so many variations that can be adopted and indeed just the salt added to the rust base colour can create rust bleeds and a kind of rust bloom or "flowering" effect that does not require a top coat...just removal of the salt.

I will post some shots of the wagons construction progress as time goes by...

The photos illustrate the workflow...

|

| And the trial fit on the incomplete underframe... |

Thursday, 12 February 2015

The Pheonix Rises...

Well it has been a while between posts...and by now I would have figured I would have posted some sort of progress on the "new" layout. As per life, there have been some twists and turns that have changed things somewhat and with family input and compromises...things are again on the move.

We had booked a local carpenter (friend) to lend us a hand to dismantle the existing layout and reconfigure the shed for business use. This work was scheduled to begin in mid January and in the meantime I had been packing and stacking the modelling items, with some being Ebayised in readiness for his arrival. In late December I began to lift some trackwork in the hope that some could be salvaged but that operation only lasted an hour or so before I lost interest due to the thought of how much time went into laying it in the first place. This one loss of destructive appetite would later play a big part in the ultimate decision making process in the hobby stakes.

In the week leading up to the shed conversion...The carpenter arrived to gain a final understanding on our requirements and to make a list all items required for the work. As we toured the layout room and the adjacent shed area, I could tell that his mind was not entirely on the task at hand and his gaze seemed to be drawn to the layout itself. At that point my wife arrived with a cuppa for us both and it was then that our contractor decided to unload. His first point of conversation was to enquire as to whether we had looked at ALL options for the business and this question was quickly followed with a friendly but expletive ridden tirade on the sanity of destroying all the many hours that had been "invested" in the layout.

Well the upshot is that he did ultimately come up with some very sound options and as at the end of January 2015...the business has ended up with much of what was required and the medium term survival of Fish River has been offered up. Secretly, the family have been watching my disposition over the last few months since the demise of the layout was first raised and it would now appear that it was not only me who was agonising over the loss. And to celebrate the reprieve I received the "homecoming" gift of a Trainorama 48 class and an Auscision 45 Class!....I should make these decisions more often! As for the planned replacement 009 layout...I will certainly be pursuing this as well, as I now have much of what is required for at least a diorama and this will lend itself perfectly to those cold winter days in the Tablelands where even a trip to the shed is a harsh decision.

And now with that all out of the way...I will end this post with my initial thoughts on the Trainorama 48 class and experience gained with my first DCC and Sound conversion in quite a while.

Out of the box it would appear that Trainorama have produced a very nice model. My model (4819) has all the attributes that we have become used to from this manufacturer and the overall appearance, paint, detail etc does not disappoint. In saying this, at least two side mirrors have been applied crookedly, the sliding window panels have no "frame" to even simulate the prototype and the side filters appear to be an added part during manufacture and mine must have been fitted on a Monday. The other appearance issue is the wiring loom running (visibly) through the cab?...surely we have gone beyond this???. Obviously everyone has differing expectations and of course this is my view only.

I decided to add the DCC Sound conversion kit to my loco and of course this requires the removal of the body which compared to the Powerline equivalent was an absolute dream....Although joy was seriously tempered during reassembly, where one needs to reattach the brake chain and this was certainly a testing task for a middle aged fart with failing eyesight and an aversion to tweezers! I have left the chain off for now!

The DCC conversion went relatively smoothly. The Trainorama supplied speaker had to be replaced due to the use of the Loksound V4 decoder and while Trainorama should be applauded for supplying a true "sound ready" locomotive, the decision to incorporate the rear lighting assembly as part of the speaker enclosure is questionable as is the choice to mount the whole assembly to the chassis with the use of tape ONLY...

As I have yet to tweak the loco under decoder-pro...I can only offer my findings based on simple programming thru NCE. There is a slight audible motor whine at low speed which should be solved thru decoder pro or running in might also see the noise diminish I am traditionally an unabashed Tsunami fan...but as I get older, the thought of pulling each loco apart to fit decoders, speakers and sort out ever increasingly sophisticated lighting circuits, has lost some of it's gloss and in the case of the 48 class ( as was the same with the 422 conversion) it was just plain easier to fit the DCC Sound offering. While the sounds of the 48 Class can only be described as brilliant, as is the horn...I was disappointed to find that CV63 ( Master Volume ) was factory set at the upper limit and my installation requires a fair increase in volume just to overcome engine noise. Maybe a variation in speaker choice could add a slight increase in volume...but as the supplied speaker is hard wired to the decoder...it should be adequate, but certainly not in my case.

Another difference between Tsunami and Loksound is the notching...where the Tsunami offering can basically work acceptably "straight out the box"....The Loksound decoder appears to only offer manual notching which is a definite deviation from my habits and could end up being a right pain in the butt...time will tell. My other fear is multiple loco lashups where the differences between the brands could see more on track "arguments" between the locos and speed matching being an absolute pain, if not impossible.

I now have a decision to make regarding the 45 class conversion and will ponder the decoder choice in the coming days...in the meantime I have included a shot of the converted 48 class.

It is nice to be back blogging the NSWGR...

We had booked a local carpenter (friend) to lend us a hand to dismantle the existing layout and reconfigure the shed for business use. This work was scheduled to begin in mid January and in the meantime I had been packing and stacking the modelling items, with some being Ebayised in readiness for his arrival. In late December I began to lift some trackwork in the hope that some could be salvaged but that operation only lasted an hour or so before I lost interest due to the thought of how much time went into laying it in the first place. This one loss of destructive appetite would later play a big part in the ultimate decision making process in the hobby stakes.

In the week leading up to the shed conversion...The carpenter arrived to gain a final understanding on our requirements and to make a list all items required for the work. As we toured the layout room and the adjacent shed area, I could tell that his mind was not entirely on the task at hand and his gaze seemed to be drawn to the layout itself. At that point my wife arrived with a cuppa for us both and it was then that our contractor decided to unload. His first point of conversation was to enquire as to whether we had looked at ALL options for the business and this question was quickly followed with a friendly but expletive ridden tirade on the sanity of destroying all the many hours that had been "invested" in the layout.

Well the upshot is that he did ultimately come up with some very sound options and as at the end of January 2015...the business has ended up with much of what was required and the medium term survival of Fish River has been offered up. Secretly, the family have been watching my disposition over the last few months since the demise of the layout was first raised and it would now appear that it was not only me who was agonising over the loss. And to celebrate the reprieve I received the "homecoming" gift of a Trainorama 48 class and an Auscision 45 Class!....I should make these decisions more often! As for the planned replacement 009 layout...I will certainly be pursuing this as well, as I now have much of what is required for at least a diorama and this will lend itself perfectly to those cold winter days in the Tablelands where even a trip to the shed is a harsh decision.

And now with that all out of the way...I will end this post with my initial thoughts on the Trainorama 48 class and experience gained with my first DCC and Sound conversion in quite a while.

Out of the box it would appear that Trainorama have produced a very nice model. My model (4819) has all the attributes that we have become used to from this manufacturer and the overall appearance, paint, detail etc does not disappoint. In saying this, at least two side mirrors have been applied crookedly, the sliding window panels have no "frame" to even simulate the prototype and the side filters appear to be an added part during manufacture and mine must have been fitted on a Monday. The other appearance issue is the wiring loom running (visibly) through the cab?...surely we have gone beyond this???. Obviously everyone has differing expectations and of course this is my view only.

I decided to add the DCC Sound conversion kit to my loco and of course this requires the removal of the body which compared to the Powerline equivalent was an absolute dream....Although joy was seriously tempered during reassembly, where one needs to reattach the brake chain and this was certainly a testing task for a middle aged fart with failing eyesight and an aversion to tweezers! I have left the chain off for now!

The DCC conversion went relatively smoothly. The Trainorama supplied speaker had to be replaced due to the use of the Loksound V4 decoder and while Trainorama should be applauded for supplying a true "sound ready" locomotive, the decision to incorporate the rear lighting assembly as part of the speaker enclosure is questionable as is the choice to mount the whole assembly to the chassis with the use of tape ONLY...

As I have yet to tweak the loco under decoder-pro...I can only offer my findings based on simple programming thru NCE. There is a slight audible motor whine at low speed which should be solved thru decoder pro or running in might also see the noise diminish I am traditionally an unabashed Tsunami fan...but as I get older, the thought of pulling each loco apart to fit decoders, speakers and sort out ever increasingly sophisticated lighting circuits, has lost some of it's gloss and in the case of the 48 class ( as was the same with the 422 conversion) it was just plain easier to fit the DCC Sound offering. While the sounds of the 48 Class can only be described as brilliant, as is the horn...I was disappointed to find that CV63 ( Master Volume ) was factory set at the upper limit and my installation requires a fair increase in volume just to overcome engine noise. Maybe a variation in speaker choice could add a slight increase in volume...but as the supplied speaker is hard wired to the decoder...it should be adequate, but certainly not in my case.

Another difference between Tsunami and Loksound is the notching...where the Tsunami offering can basically work acceptably "straight out the box"....The Loksound decoder appears to only offer manual notching which is a definite deviation from my habits and could end up being a right pain in the butt...time will tell. My other fear is multiple loco lashups where the differences between the brands could see more on track "arguments" between the locos and speed matching being an absolute pain, if not impossible.

I now have a decision to make regarding the 45 class conversion and will ponder the decoder choice in the coming days...in the meantime I have included a shot of the converted 48 class.

It is nice to be back blogging the NSWGR...

Subscribe to:

Comments (Atom)